How to Dry Drywall Mud Faster + How Long It Takes

Is there a way you can increase the rate at which drywall mud cures during drywall finishing? Most people don’t realize that one of the most important aspects of drywall installation is letting the compound cure for 2-3 days or at least 24 hours. The slower you let your drywall mud air out, the better it will be at handling any bumps or scrapes that might happen in the future.

The best way to dry drywall mud faster is by running a dehumidifier in the room to reduce moisture in the atmosphere. Alternatively, use hot joint compound for your applications, apply thinner coats, or run a drying gun to reduce the curing time of your drywall compound.

How long does drywall mud take to dry?

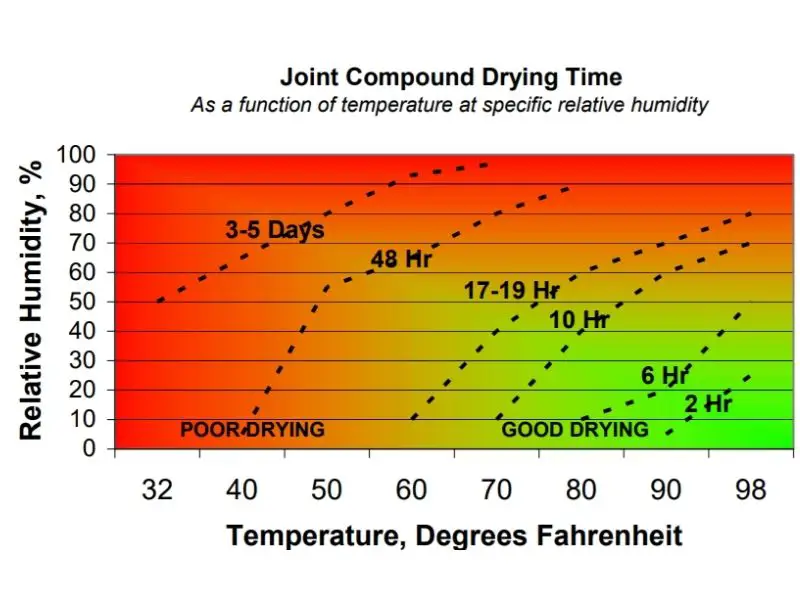

A coat of drywall mud takes about 24 hours to dry when the temperature is about 70°F and humidity at 70% or lower. The curing time varies depending on the thickness of the joint compound, depth of application, humidity levels, and temperature. Always allow the mud to dry before applying a new coat.

As a rule of thumb, allow every coat of drywall mud to cure for at least 24 hours before sanding, painting, or applying the next coat. If you prefer a faster curing time, use setting compound instead of regular joint compound as it can dry as fast as 5 minutes after application depending on the type.

Avoid painting over wet drywall mud at all costs because that could increase the shrinkage of the joint compound. Fortunately, there are a few ways you can shorten the drying time by up to half, as I’ve discussed in the next section.

How to Dry Drywall Mud Faster

It can take quite a long time for your joint compound to cure especially if you’re applying several coats. The type of compound can also determine how long it will take for it to be safe to apply the next coat. The good thing is, there are a few hacks you can try to make the mud cure faster.

Here’s how to dry drywall mud faster:

1. Apply light coats (thin layers)

Lighter coats of joint compound dry faster than thicker applications. Apply thin layers which allow for better ventilation, as well as quicker drying times. The initial coat is usually required to be the thickest and should thus be allowed no less than 24 hours of drying time. Subsequent coats can then be thinned out if your goal is to dry the joint compound faster.

Note that by mixing the compound with less water and using latex primer or adhesive instead of joint compound on joints can help cut drying times down from over 30 hours for some types of mud to around 12 hours.

2. Run a dehumidifier in the room

Since drywall mud has moisture, running a dehumidifier in the house for at least 10 hours will reduce the drying time significantly. The optimal relative humidity range for curing drywall mud is 20-40%.

If you don’t have a dehumidifier, you can prep the room for mudding a few days prior by installing fans to improve the air circulation. The breeze generated by the fans will reduce the humidity levels.

Take caution when using artificial or natural wind (opening windows) to create better ventilation for faster setting of drywall mud. Such forcefully blown air when coupled with low-temperature conditions can trigger freezing of the joint compound prior to curing. Painting partially frozen joints can lead to structural problems such as bulging drywall panels over time.

3. Use hot joint compound

Hot drywall mud is a powder that’s mixed with water to form a joint compound that cures within 20-60 minutes. This is a fast drying time given drywall mud can take up to 24 hours to dry.

The downside to such an extremely fast curing time is that it doesn’t leave much room for error correction.

Since you don’t want the hot mud drying up before applying it, mix just a bit of it on your mud pan as you go along. Finally, once you’re done with the application, wash your mud pan to prevent residual hot mud from setting on it.

4. Using a drying gun

A drying gun is a device that helps speed up the drying process by directing electric heat to surfaces.

In order for it to work, you need joint compound in your taping knife or roller and then apply it sparingly over the surface of one side of the tape line. If there are several drywall panels around a corner, cover each panel with mud before drying guns have time to cool down.

Once applied on both sides of taped joints, point the heating nozzle at the area until the desired temperature is reached, which can take from 30 seconds – 60 minutes depending on the size and shape of the room.

Once satisfied with results retreat edges again like when using traditional methods but this time use a fan if available to help circulate air evenly throughout the room otherwise just let the wall dry out naturally.

5. Sand each layer properly before applying a new one

Sand each sand before applying a new layer of mud. This will help the drywall to hold up better against bumps and scrapes in the future, while also speeding up drying time because sanding smoothes out air pockets that trap water vapor from the curing compound.

What temperature does drywall mud need to dry?

Joint compound dries fastest when the room temperature is between 65°F-80°F. Avoid mudding your drywall when it’s too cold because the joint compound will take much longer than 24 hours to cure and lead to structural problems. Drywall mud that stays wet for too long softens the edges of the panels.

If you’re installing drywall sheets in cold weather, you’ll need to install an artificial heating system to set the appropriate room temperature for the mudding process. However, do not overheat the room, as temperatures exceeding 95-degrees Fahrenheit may trigger the following problems:

- The high temperatures will cause the moisture content inside the gypsum crystals to evaporate, thus causing damage to the structural core of the boards.

- Poor bonding capability of joint tape to the surface of the drywall panels.

- Excessive shrinkage of the joint compound due to the drywall mud setting way too fast. Some drywall applications will start crumbling later because of this.

In light of the above precautions, you may want to follow the proper room heating techniques when applying sheetrock mud in winter weather. For starters, avoid installing space heaters facing directly towards the drywall.

In addition, warm the room and drywall surface that you’re finishing to a temperature of no less than 50-degrees Fahrenheit for two days prior to mudding. Such surface prep allows for a quicker drying time.

Third, acclimate the joint compound to the temperature conditions of the working surface by leaving it in the room for at least 48 hours prior to application.

Finally, when using fueled heaters, ensure to create additional air circulation. That’s because a lot of water vapor is released into the air during combustion when using these types of heaters. Since high humidity slows down the curing rate of drywall mud, extra air circulation cancels out the rise in relative humidity.

Note: It’s important to take the necessary safety precautions when using temporary artificial heaters to warm your drywall surface in preparation for mudding. You don’t want to start a fire.

How to tell if joint compound is dry

Relying on the manufacturer’s guideline to tell whether joint compound is dry enough to be painted over can be misleading, as the drying rate varies depending on various locational factors. To accurately determine whether your drywall mud has cured, feel it using your palms.

If it has a cold, clammy feel, it’s still wet. Wet joint compound also has patches that are darker than the shade at the edges

Can I dry joint compound with a hair dryer?

You can use a hair dryer to speed up the drying of drywall mud. This technique is most effective when drying thin coats of joint compound. Using a hair dryer won’t significantly improve the drying rate of thicker layers. A good alternative to a hair dryer is a heat gun.

The hairdryer not only increases the temperature of the wall area it is targeted at but also helps to lower humidity by blowing air for improved circulation.

One major downside to using a hairdryer- though- is that it is applied directly to the targeted area, which can cause the joint compound to shrink too much and crack, forcing you to repair by applying additional layers

Note: When looking to speed up the cure time of drywall mud using this method, don’t leave your hair dryer running unattended as this is unsafe. Also, while faster drying of drywall mud shortens the timeline of finishing projects, letting the joint compound cure naturally will deliver the best results.

References

- Michael Gardner, All Things Gypsum: Heating and Ventilating a Room to Dry Joint Compound

- Drywall Finishing Council: JOINT COMPOUND DRYING TIME – The Impact of Environmental Conditions