Fiberglass vs Cellulose Blown Insulation – Which One is Better?

When advising my clients on which type of insulation to choose, they always ask me, “What’s the difference between fiberglass and cellulose insulation?” Fiberglass and cellulose are two insulation methods popular for their minimal price difference. However, their differences might influence your choice for your next insulation project.

Cellulose blown insulation is great for cold climates because it retains form and R-value over a long period. It also has better airflow and heat regulation. However, fiberglass is more affordable and is available as batts and blown-in options.

What is fiberglass insulation?

Fiberglass insulation is insulation material made from fine glass fibers that insulate your home by generating numerous air pockets that enable convective and conductive heat flow.

This type of insulation is installed in unfinished floors, ceilings, and walls during construction. The contractor places the fiberglass insulation material between joists, beams, or studs.

You can purchase fiberglass insulation as batts, rolls, boards, or loose-fill. Fiberglass insulation rolls are generally large and can be used to cover wall-to-wall, or from one end of the ceiling frame to the other.

On the other hand, fiberglass batts are generally smaller and can be easily installed in pieces as a DIY project.

Note: To make fiberglass insulation material, the vitreous melt is shaped into fibers using heat.

Blown-in fiberglass is usually in loose-fill form and is used to insulate hard-to-reach areas such as around wiring in the wall cavity. Blown-in fiberglass insulation is crucial, as small insulation gaps can result in inefficient thermal performance.

Fiberglass boards are easy to install over drywall, concrete, and wood. DIY enthusiasts prefer fiberglass insulation boards for ceiling and wall insulation due to their ease of insulation.

What is cellulose insulation?

Cellulose insulation is a type of building insulation material made from recycled paper products. Waste paper products such as used cardboard boxes and old newspapers are shredded and mixed with fire retardants to make blown-in cellulose insulation.

Boric acid, ammonium sulfate, and borax are commonly used fire retardants. These chemicals are approved for use since they’re the least hazardous. Recycled paper content forms 85% of cellulose insulation, while flame retardants make up the remaining 15%.

There are three types of cellulose insulation; loose-fill cellulose insulation, dense-packed cellulose insulation, and wet-applied spray cellulose insulation. While the first two can be used on new and existing constructions, wet-applied spray cellulose insulation is only installed in new constructions before drywall installation.

For blown-in cellulose insulation in existing buildings, you need to remove a strip of the external siding and drill 3-inch holes into each stud cavity. Then, using a special filler tube, you should blow the cellulose filling into the cavity before plugging the holes. Finally, replace the exterior siding.

Cellulose insulation improves your home’s thermal insulation and makes it more soundproof. Also, its flame retardants prevent pests and mold that can damage your drywall walls and ceilings.

Fiberglass vs. Cellulose Blown Insulation – Key Differences

Both fiberglass and cellulose insulations are susceptible to moisture damage. Both can be mixed with other types of insulation material and can be used to provide thermal sealing.

However, these few similarities can’t match the several differences between fiberglass and cellulose.

The main differences between fiberglass and cellulose-blown insulation are their costs, eco-friendliness, insulation capacity, and longevity.

Insulation capacity

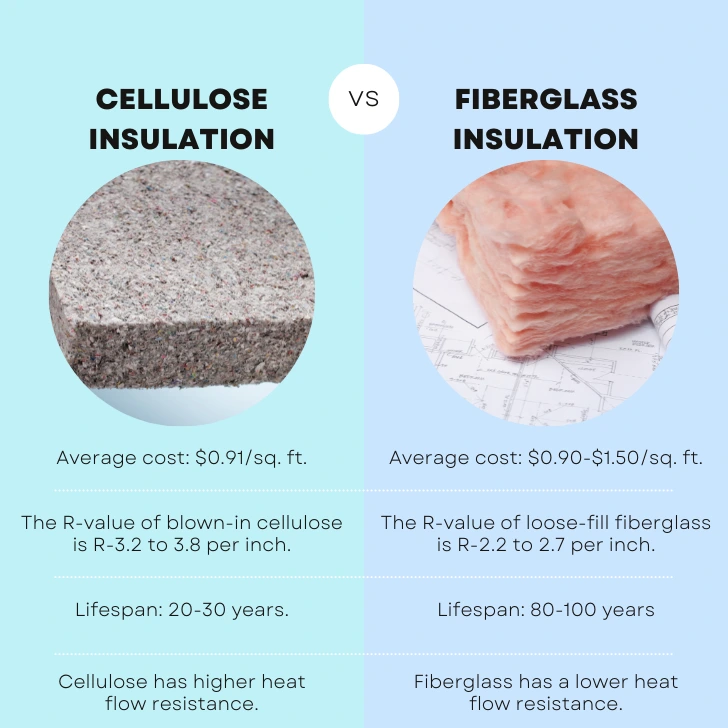

The R-value of blown-in cellulose is R-3.2 to 3.8 per inch, while the R-value of loose-fill fiberglass is R-2.2 to 2.7 per inch. As such, cellulose insulation is more effective than fiberglass insulation.

The insulation capacity of a material is measured using the R-Value – a measure of the conductive heat flow resistance of the material.

Fiberglass insulation loses some R-value when densely packed or in extremely cold conditions. Meanwhile, cellulose insulation can be compressed with minimal loss of R-value, and will retain its R-value even at freezing temperature.

Durability

The typical lifespan of cellulose insulation is 20-30 years. Fiberglass insulation boasts better longevity than cellulose insulation. Over time, cellulose insulation tends to pack and settle, losing its R-value in the process and forming pockets in the sections where it has settled. These pockets allow hot or cold air transfer into the home, lowering insulation efficiency.

Comparatively, fiberglass insulation retains its shape and form over its 80-100-year lifespan. This is why fiberglass insulation products typically come with a lifetime warranty.

Costs

Fiberglass insulation is generally cheaper than cellulose insulation. The average price of fiberglass insulation is $0.91 per square foot, whereas blown-in cellulose costs $0.90-$1.50 per square foot.

You can still find cellulose insulation that costs less than blown-in fiberglass insulation. However, fiberglass insulation is also available as batts, which are more affordable, with prices as low as $0.30 per square foot.

Eco-friendliness

Cellulose insulation is more eco-friendly than fiberglass. Not only is it made from recycled paper content, but it is also biodegradable. Cellulose forms fewer thermal bridges, making it more effective in airflow regulation and energy saving.

On the other hand, fiberglass insulation is made of molten glass particles and doesn’t decompose. You can get denser variants that are more effective in cramped spaces.

Health and safety

Blown-in cellulose insulation is considered safer than fiberglass insulation because it is made of recycled paper content, which doesn’t present any significant health and safety concerns.

Furthermore, the retardants used to treat cellulose insulation aren’t toxic to humans. Still, you’ll need to wear a respirator mask to avoid inhaling paper dust.

On the contrary, fiberglass insulation is known to cause nose and throat inhalation if inhaled during installation. This is why it’s important to wear a dust mask when installing fiberglass insulation. What’s more, it also causes skin irritation.

Availability

You can purchase fiberglass rolls, batts, or loose-fill fiberglass. Cellulose insulation is only available as loose-fill.

This difference has some advantages and disadvantages on either side. You can choose to install fiberglass batts which are more cost-friendly, then fill up the hard-to-reach cavities with loose-fill fiberglass to save more costs.

However, installing fiberglass batts might be hard. You might have gaps where the batts are sagging, bunched up, or torn. Blown-in cellulose may cost more, but it’s easy to install, and you can fit it into all spaces and cavities.

Here’s a summary of the differences between blown fiberglass insulation and blown cellulose insulation.

| Blown fiberglass insulation | Blown cellulose insulation |

| The average cost of blown fiberglass insulation is $0.91 per square foot | Blown-in cellulose insulation costs $0.90-$1.50 per square foot. |

| Fiberglass does not decompose as it’s made of glass | Cellulose is biodegradable since it’s made of paper |

| R-value of R-2.2 to 2.7 per inch | R-value of R-3.2 to 3.8 per inch |

| Has lower heat flow resistance | Has better heat flow resistance |

| 80-100 year lifespan | Shorter lifespan of 20-30 years |

| Inhalation can lead to nose and throat irritation, while physical contact can lead to skin irritation | Non-toxic to humans |

| Mixes well with fiberglass batts | May cause reduction in R-value if mixed with fiberglass batts |

Which one is better: cellulose or fiberglass insulation?

Your choice depends on your needs, location, and budget.

But suppose you were to compare fiberglass and cellulose blown insulation, I recommend that you go for blown-in cellulose insulation if you live in a cold region since it handles cold weather better than fiberglass insulation.

Conversely, fiberglass insulation is the better option if you’re looking for a lifetime insulation solution since it can last up to 100 years.

Can you mix cellulose and fiberglass insulation?

You can combine fiberglass insulation with cellulose insulation, a process professionally known as capping.

Capping saves time and money that you would otherwise spend on removing the old insulation before replacing it with the new one.

Removing existing fiberglass batts from the wall paneling is complex and time-consuming. Blowing in cellulose insulation on top of the existing fiberglass insulation batts/rolls for added insulation is more practicable and economical.

However, capping has a downside; the cellulose particles can infiltrate the air pockets inside the molten glass particles that make up the fiberglass insulation, reducing the R-value.

MORE ABOUT INSULATION:

References

- Electronic Library of Construction Occupational Safety and Health: NIOSH Exposure Assessment of Cellulose Insulation Applicators

- Connecticut Department of Public Health: Insulation And Your Home- Health Considerations